OIL & GAS

Business Segments

Oil & Gas segment supplies products, spare parts and services to the Oil & Gas Industry such as Heat Exchangers, Pumps, Gas Compressors, Gas Turbine, Air intake Filtration system, Pressure Vessels, Tanks, Pipes, Valves, Oil & Gas separation & Filtration, process equipments, Heat management Solutions and Separator Vessel Internals & Consultancy Services, etc.

Our Partners

- ALFA LAVAL

- CLYDEUNION

- PENTAIR

- ALTAIR

- ZETA-PDM

- METALTEK

- CARPENTER & PATERSON

- RBR

- PARESA

- HOWDEN

- GASCO

- JINDAL SAW

- GAS TURBINE SERVICES

- JONELL SYSTEMS

- PARKER

- QUARTZELEC

Alfa Laval is today a world leader within the key technology areas of heat transfer, separation and fluid handling.

Alfa Laval was founded on a single brilliant invention and innovation remains at the heart of everything they do.

Plate Heat Exchangers – Brazed plate heat exchangers, Fusion-bonded plate heat exchangers, Gasketed plate-and-frame heat exchangers, Spiral heat exchangers, Welded plate-and-block heat exchangers, Welded plate-and-frame heat exchangers, Welded plate-and-shell heat exchangers. Automatic back flushing filters. Centrifugal separators.

Alfa Laval is a leading global supplier of products and solutions for heat transfer, separation and fluid handling through their key products – heat exchangers, separators, pumps and valves.

Alfa Laval is known for focusing on innovation and new ways of thinking since its inception. Alfa Laval makes continuous and consistent investments designed to build, strengthen and develop the company’s global market leadership.

Alfa Laval is known for focusing on innovation and new ways of thinking since its inception. Alfa Laval makes continuous and consistent investments designed to build, strengthen and develop the company’s global market leadership.

Alfa Laval currently holds more than 2000 patents and invests approximately 2.5 percent of its sales in research and development launching between 35 and 40 new products every year.

Alfa Laval currently holds more than 2000 patents and invests approximately 2.5 percent of its sales in research and development launching between 35 and 40 new products every year.

Alfa Laval’s worldwide organization helps customers in nearly 100 countries to optimize their processes. Alfa Laval has 42 major production units (15 in Europe, 8 in Asia, 4 in the US and 1 in Latin America). The company has over 18 000 employees, the majority of whom are located in Sweden, Denmark, India, China, the US and France.

ClydeUnion Pumps has over 140 years of experience in pumping technologies and has a rich heritage of product brands.

May 2007 saw the formation of Clyde Pumps through the acquisition of Weir Pumps, a long-standing engineering company with roots dating back to 1871. Following was the acquisition of Union Pumps in November 2008, which formed ClydeUnion Pumps. The joining of these companies brought together some of the most respected products, people and heritage brands in the business including the more recent addition, S&N Pumps, who specialise in technologies for exploration and marine markets.

In December 2011, ClydeUnion Pumps, became part of SPX Corporation allowing SPX to grow its network of pump expertise and operations including eight additional manufacturing facilities and 25 global service centres. The purchase of the company is consistent with SPX’s long-term strategy to expand its flow technology capabilities and establish a global platform in the power and energy sector. The ClydeUnion Pumps product range compliments the existing SPX portfolio of brands which include APV, Bran + Luebbe, Johnson Pump, Plenty and Lightning.

Industries

ClydeUnion Pumps brand is known worldwide for supplying reliable and robust engineered pumping solutions stemming from over 140 years of industry expertise. Their experience spans across several complex industries including oil and gas, nuclear and conventional power generation, desalination and other key markets relevant to our product portfolio.

Exploration

ClydeUnion Pumps provides superior engineered solutions for the offshore exploration and marine industry. These include products for offshore oil, gas exploration, and marine vessels, as well as the offshore wind industry.

The acquisition of S&N Pumps which formed, ClydeUnion S&N Pumps, enhanced the company’s experience and expertise in the oil & gas exploration sector. ClydeUnion S&N Pumps has been providing water systems and related accessories to the offshore drilling and production industry for more than fifty years allowing us recognition as the world’s leader in offshore water support; specializing in the supply and repair of submersible pumps and motors.

The acquisition of S&N Pumps which formed, ClydeUnion S&N Pumps, enhanced the company’s experience and expertise in the oil & gas exploration sector. ClydeUnion S&N Pumps has been providing water systems and related accessories to the offshore drilling and production industry for more than fifty years allowing us recognition as the world’s leader in offshore water support; specializing in the supply and repair of submersible pumps and motors.

Upstream

ClydeUnion Pumps, an SPX Brand provides superior solutions to Oil & Gas Companies in upstream, production, transportation, refining and related petrochemical industries.

Upstream products include well service, stimulation pressure pumping, and flow control products. Engineered mechanical and rotating equipment repairs and upgrades, oilfield and drilling equipment repair and certification are covered in our selection of highly skilled aftermarket services.

Upstream products include well service, stimulation pressure pumping, and flow control products. Engineered mechanical and rotating equipment repairs and upgrades, oilfield and drilling equipment repair and certification are covered in our selection of highly skilled aftermarket services.

Downstream

ClydeUnion Pumps has within its product range all the Downstream Oil products of Union Pump and Clyde Pumps providing us with not only an extensive product portfolio

but also a history of experience and knowledge of the industry. ClydeUnion Pumps provide products for the downstream industry that can handle the pressures and demands of modern downstream oil processing.

Pentair Thermal Management offers pipe freeze protection as a complete heat management system, which includes the selection of industrial heat trace technologies and advanced control system technologies, in addition to turnkey services.

Zeta Pdm is a specialist technology supplier to the oil, gas, water and petrochemical industries, focusing on the supply of advanced separation solutions for the many types of multiphase flow processes encountered in this field.

Radiant Coils, Auxiliary Boiler Coils, Heat Exchangers and Steam

Generators. Convection Coils, Pigtail Assemblies, Piping Overlays and Boiler Coils Refractory Lined Transfer Lines, Waste Heat Boilers and Reactor Coils.

Pressure Vessels and Drums, Inlet Manifolds and Hot Collector Urea Reactor Repairs and Methanators.

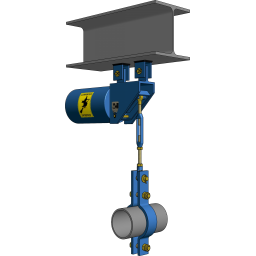

Pipe Support – Constant & Variable Load Effort Spring Units, Cryogenic Support.

Design and Detail of complete Pipe Support Systems

Carpenter & Paterson Ltd is a wholly independent British company based in Welshpool, United Kingdom.

Witch-Hanger

The company RBR was founded in 1964 by the present owners and immediately affirmed its presence on the market amongst the most well-known leading manufacturers of valves for industrial applications.

For more than 35 years RBR has designed, engineered, manufactured and delivered BALL VALVES which are installed and successfully perform in various plants world-wide.

PARESA was established in Italy in 1978, rapidly growing from shop manufacturing of storage tanks to the execution of turnkey projects.

PARESA designs, fabricates, constructs, repairs and refurbishes any kind of storage facilities, from the simplest to the most sophisticated ones, providing a wide variety of services and cost-effective solutions to key industries including refineries, terminals, depots, power plants and more.

Products

ATMOSPHERIC LOW PRESSURE TANKS

SPHERES

LOW TEMPERATURE CRYOGENIC TANKS

PRESSURE VESSELS

PENSTOCKS

GASHOLDERS

Originally founded by James Howden in Scotland as a marine engineering firm in 1854, Howden has grown and evolved into a leading global engineering business manufacturing air and gas handling solutions.

With the power of their engineering expertise and technology, Howden equipment plays an integral role within our customers’ processes, which provide safe and reliable products, solutions & services that are both sustainable and efficient.

Howden supports multiple sectors including infrastructure, power generation, oil & gas, wastewater, metals, mining and transportation.

Products

The widest range of rotating equipment to help solve the toughest application engineering challenges:

Fans

Our Configured Centrifugal & Axial Fans are ideal for lower volume requirements, while our Engineered Centrifugal & Axial Fans are core in many heavy industries. Our Cooling Fans are the quietest options you can buy.

Heaters

Rotating Heat Exchanger technology is core in many heavy industries like Power Generation. It also proves value in other industries as a way to limit harmful emissions. We offer a wide range of element profiles to suit any situation.

Compressors

We offer a complete range of compressors, both oil free and oil-injected Screw Compressor technology, Reciprocating and Diaphragm Compressors to cope with the highest pressures, high-efficiency Centrifugal Compressors.

Blowers

For the blower market we own the world’s most recognizable brands. HV-TurboTM and TurblexTM are world-leading Turbo Blowers for environmental markets, Howden’s range of SG blowers offer high-efficiency solutions, and for Rotary Blowers, RootsTM is the most trusted name in the world. For high volume requirements we provide Turbo Fans.

Steam Turbines

We provide Steam Turbine solutions for all customer demands – from the simple CORE for packagers, up to extensively customised/engineered systems within the range up to 24 MW. The most economical and flexible turbines that you can get.

Parts & Service

Spare Parts

Spare Parts

Genuine & quality OEM parts ensure safe & impeccable performance. Fast turnaround time from order to delivery via our specialist aftercare team.

Service

Service

Locally based engineers, skilled in rotating equipment for your applications, are ready to be with you at your site, when you need them. During the COVID-19 pandemic, Howden can still support all your service needs using Remote Assistance powered by Vuforia Chalk.

Retrofits

Retrofits

Extend your equipment’s life with Howden Upgrades & Retrofits, and benefit from advancements in technology to make your process more efficient.

Digital Solutions – Howden Uptime

Digital Solutions – Howden Uptime

Uptime is a unique & innovative platform for gathering, interpreting & analyzing rotating equipment data. Built on the foundation of 160 years of OEM experience, and powered by Microsoft Azure & PTC ThingWorx, Uptime is a radical step forward in managing equipment performance, and is remarkably easy to install & use. Uptime provides a unified view, anytime and anywhere, of your rotating equipment health.

COMBUSTION, PROCESS AND THERMAL ENGINEERING

Gasco Pty Ltd has established a reputation as Australia’s leading combustion and process engineering company.

Gasco was formed in 1991 and is an independent, 100 per cent Australian-owned company. Its board and management are acknowledged for their experience and expertise in the industry.

Gasco, with its highly skilled, multicultural staff and its modern office and manufacturing facility, is able to offer a comprehensive range of equipment and services including design, engineering, project management, fabrication, installation, commissioning and service.

Gasco has a wide range of clients across various industries including oil and gas both onshore and offshore power generation, environmental, mining, mineral, chemical processing, refining and petrochemical, food, automotive, waste water treatment and biogas.

Gasco clients include Shell, Petronas, Exxon Mobil, BP, Chevron, Conoco Phillips, Toyota, Boeing, Total, Dolphin Energy, Jemena, AGL Energy Australia, Origin Energy, APA Group, Orica, BHP Billiton, Bechtel, KBR, Worley Parsons, Clough, Uhde Shedden, Technip, Santos, Wood Group PSN, Oil Search, Power & Water, Pertamina, Foster Wheeler, Zadco and many others.

Gasco has supplied Fired Heaters to Pakistan, Turkmenistan and UAE, Smelter Burners to China and India, Crude Oil Gas Heaters to Russia, Thermal Oxidizers to Pakistan, Hot Oil Heaters to Indonesia, South Africa, Tanzania, Malaysia and the Philippines, Convective Condensate Heaters to Thailand, Flares to Vietnam, Gas Skids to Bahrain, Burner Management System to UAE and Fuel Gas Skid package to Oman.

Gasco holds ASME “U”, “U2” and “S” stamps for the design and manufacture of Pressure Vessels and power to Power Boilers, and a National Board of Boiler and Pressure Vessel Inspectors (“R” Stamp) to repair Pressure Vessels and Boilers to NBIC Codes.

Gasco has been presented with Industry Achievement Awards from ICN and Innovation Australia and Directors Award from Santos for EHS performance.

Quality Assurance and Health and Safety are key aspects to all our projects. Gasco is certified by DNV to the requirements of ISO 9001:2008.

THE O.P. JINDAL GROUP

Jindal SAW is a part of renowned Jindal Organization.

The Jindal Organization was set up in 1970 by the steel visionary Mr. O.P. Jindal. Jindal has grown from an indigenous single-unit steel plant in Hissar, Haryana, India to the present multi-billion, multi-location and multi-product steel conglomerate. The organization is continuously expanding, integrating, amalgamating and growing in new directions and with new objectives, still the Jindal motto remaining the same, “We Are the Future of Steel”.

The Jindal Organization is a celebrity with special status in the Iron & Steel sector. Ranked sixth amongst the top Indian Business Houses in terms of assets, the Group today is a US $18.5 Billion conglomerate, spread over 13 plants at 10 pivotal locations in India and various plants across the globe.

JINDAL SAW LIMITED (Formerly SAW PIPES LTD)

Jindal Saw Ltd., (JSL) is a Total Pipe Solutions Company and a leading manufacturer of Large Diameter Submerged Arc Welded Pipes, Ductile Iron Pipes and Seamless Pipes and Tubes.

The company has a sales turnover in excess of US $ 1 Billion and has 4 manufacturing locations in India and one location in Baytown, Houston, Texas (USA)

SEAMLESS TUBES DIVISION

The Seamless division produces Tubes & Pipes at a state of the art plant at Sinnar, which is approx. 205 Kms from Mumbai near Nashik in Maharashtra State, India, with technology & equipments from MANNESMANN DEMAG Huttentechnik-MEER of Germany, acknowledged world leaders in Seamless Tube & Pipe technology.

Our plant has annual installed capacity of 220,000 M Tons for Carbon & Alloy Steel Pipes and is equipped with modern manufacturing machineries and latest testing facilities including Fusion Bonded Epoxy (FBE) and 3 layer Poly Ethylene (LPE) & 3 Layer Poly Propylene (LPP) External Anticorrosion Coating Line.

Product Mix Comprises :

- Line Pipe /Process Pipe

- OCTG – Casing & Tubings

- Drill Pipes

- Boiler & Heat Exchanger Tubes

- Bearing Steel Tubes

- Mechanical Tubes

- Tube for Hydraulic Cylinder Application

Size Range:

- Carbon & Alloys steel : 1/2″ To 8″ OD

- Stainless Steel : 1/2″ to 55″ OD (Seamless & Welded)

- Drill Pipe :2-3/8″ to 6-5/8″ OD

Jindal Saw Ltd. have been doing business since decades in GCC countries with regular supplier of ADNOC , GASCO , SOC , KNPC , KOC.

CERTIFICATIONS :-

- ISO 9001:2008, ISO 14001:2004 & BS OHSAS 18001: 2007 certification by TUV, Nord.

- API 5L, API 5CT & API 5DP

- PED Certification by DNV

- Well Known Tube/Pipe maker under Indian Boiler Regulation.

Further, leading third party inspecting authorities like EIL, LRIS, Bureau-Veritas, DNV, TUV etc. regularly visit our works for inspection against various customer orders.

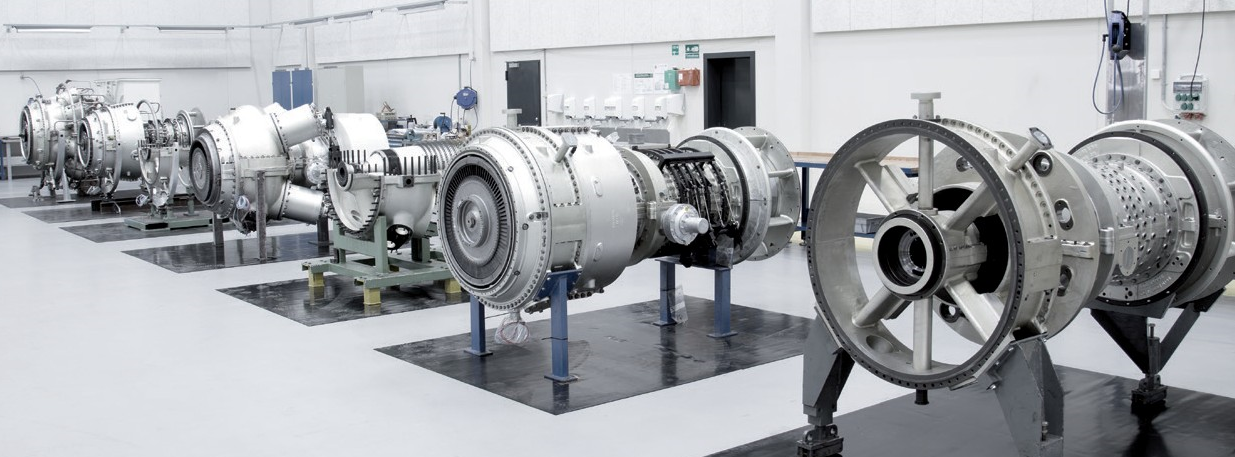

Gas Turbine SERVICES

Gas Turbine Services (GTS) is one of the largest ISP’s in mainland Europe offering onshore and offshore maintenance services for the Siemens (Lincoln) SGT/Ruston range of engines, specifically TA, TB5000/5400, SGT-100, SGT-200 and SGT-300.

Since forming in 1985, Gas Turbine Services (part of the Anglo / Danish ‘HKJ Group’) has specialised in the provision of ‘High Quality’ cost effective aftermarket Service Support for the Siemens SGT range of engines.

GTS was the OEM approved Regional Service Centre for Siemens SGT Products from 2000 through to 2015. The strategic decision to end the long established Service Centre Agreement was implemented in order to expand their global presence and customer base. GTS now provide support for the SGT/Ruston fleet around the world from their offices and workshop facilities located Esbjerg (Denmark), Lincoln and Aberdeen (UK).

GTS’s 30+ years of experience enables them to deliver turnkey maintenance support – including:

- Field maintenance / specialist manpower & tooling

- Capital and consumable parts

- Gearbox overhaul or exchange

- Controls system support – remote and onsite trouble shooting, health checks, card repairs, new card supply and controls upgrades

- Core engines (Gas Generators and/or Power Turbines) from GTS stockholding on a sale, lease or exchange basis.

- Flexible / tailored long term maintenance solutions and LTSA’s

Jonell Systems Designs and Manufactures Innovative Filtration Solutions

Jonell Systems was formed when Jonell, a company recognized for innovative, custom-designed filtration cartridge solutions and its customer-centric approach joined with Nowata (formerly known as MAHLE) to deliver end-to-end high performance filtration solutions.

Our solution range addresses the filtration and separation needs of oil & gas, petrochemical, chemical and power customers worldwide. It includes innovative filtration cartridges with a wide range of media options and well-designed filter housings to provide complete solutions and systems.

Jonell Systems can design, engineer, fabricate and manufacture cartridges, housings and systems so that our customers know their equipment and processes will operate at both the efficiency and throughput they require. We also have a range of services to support our customers.

Filtration application solutions range from injection water in upstream applications to fuel filtration in storage tanks and natural gas in power plants downstream.

As a part of Filtration Group, the world’s fastest growing filtration company, it is our mission to make the world safer, healthier and more productive.

Filtration Product Range

Housings + Cartridges + Systems = Total Filtration Solutions

Gas Filtration Liquid Filtration Systems

With 50 years’ experience in gas turbine inlet filtration, Parker knows how to develop and produce high quality gas turbine air inlet filters and systems that provide superior performance in a wide range of environmental conditions. Whether you need a cartridge, vCell, pocket or panel filter or a complete gas turbine inlet filtration system, Parker’s filtration solutions portfolio is designed to meet your operating goals.

When it comes to selecting the right filter for your needs, Parker’s Clearcurrent and altair® filter portfolio offers extremely high levels of turbine protection for a wide range of environments. Parker’s filter elements are designed to fit a range of new and retrofit systems and are available in various sizes and materials of construction.

Founded in 1966, altair became known as a specialist in offshore filtration while skillfully branching into other areas of filtration. Acquired by General Electric in 2006 and renamed GE Air Filtration, the altair brand was left to continue while utilizing the GE expertise in gas turbine design to further refine the right criteria for proper inlet filtration. The Clearcurrent name and history is now a key product and brand for Parker Gas Turbine Filtration.

Through our clearcurrent and altair brand, Parker GTF has real world knowledge that will help you get more output and more reliability from your machine.

![]()

Parker’s clearcurrent® filters offer superior support to the Energy & Electric Utilities market. This comprehensive group of product solutions focuses on the needs of power generation suppliers to help achieve increased power output, lower heat rate, predictable and lower pressure loss and reduced fouling. Driven by market leading research and development, clearcurrent filters help deter gas turbine degradation leading to more MW being delivered on the gas turbines they protect.

QUARTZELEC | ELECTRICAL ENGINEERING SERVICE PROVIDER

An independent organization and an unrivalled service partner in both UK and Global markets, employing 630 people with a turnover in excess of £76million – Quartzelec is a technical authority specialized in the field of rotating electrical machines, supporting the OEM and owner/operator for new equipment as well as the maintenance, repair and operators market.

2017 saw Quartzelec celebrate 10 years of OEM independence as well as a 100-year heritage, continuing to build their reputation as a high quality, cost effective provider of engineering services.

The Quartzelec organization supports initial design through to successful installation and commissioning with ongoing maintenance to ensure continued efficiency and safety of your processes, coupled with a complementary portfolio of specialist services available through specific Quartzelec companies.

Rotating Equipment | Services

Key Capabilities

Lifetime care and maintenance packages including long term service agreements (LTSA’s) and life extension programs (LEP’s)

Lifetime care and maintenance packages including long term service agreements (LTSA’s) and life extension programs (LEP’s)- Machine outage works (annual, minor and major inspections together with diagnostic testing)

- Machine refurbishment, repair and rewinds

- Machine upgrades

- Source, supply as well as design & manufacture of component and capital spares

- All HV, mechanical and NDT testing activities for rotating plant

- Support for all OEM manufactured equipment

- 24/7 support service

Machine Scope

Extensive Experience in the repair, overhaul, rewind, refurbishment and service of:

Extensive Experience in the repair, overhaul, rewind, refurbishment and service of:

- AC Motors up to 13.8kV

- AC Generators including turbo alternators up to 500MW

- DC Motors

- DC Generators

- AVR’s / Excitation Systems

- Mechanical scope; Pumps, Fans, Gearboxes etc.

Service and Maintenance Options

Quartzelec can provide a tailored scope, suggesting various maintenance and refurbishment solutions including:

- Design and machine engineering

- Repair and refurbishment

- Installation and commissioning

- Site service

- Major overhauls

- Long Term Service Agreements

- Diagnostics and life assessment testing

- New equipment and spares supply

Oil and gas operations are often situated in remote locations. They require high availability and low downtime rates from their gas turbines, all while battling harsh weather conditions, high levels of airborne particulate and salt ingress. CLARCOR Industrial Air and the altair name symbolizes delivering solutions that bring air quality to your turbine, improve gas turbine availability and provide extended operational capability, whether your operation is located offshore, on an FPSO, a coastal LNG refinery or any point in between.

Oil and gas operations are often situated in remote locations. They require high availability and low downtime rates from their gas turbines, all while battling harsh weather conditions, high levels of airborne particulate and salt ingress. CLARCOR Industrial Air and the altair name symbolizes delivering solutions that bring air quality to your turbine, improve gas turbine availability and provide extended operational capability, whether your operation is located offshore, on an FPSO, a coastal LNG refinery or any point in between. Pipe Hangers & Supports

Pipe Hangers & Supports